Double Roof Sheet Rolling Machine

Basic Info

Model No.: KYT

Product Description

Double Roof Sheet Rolling Machine

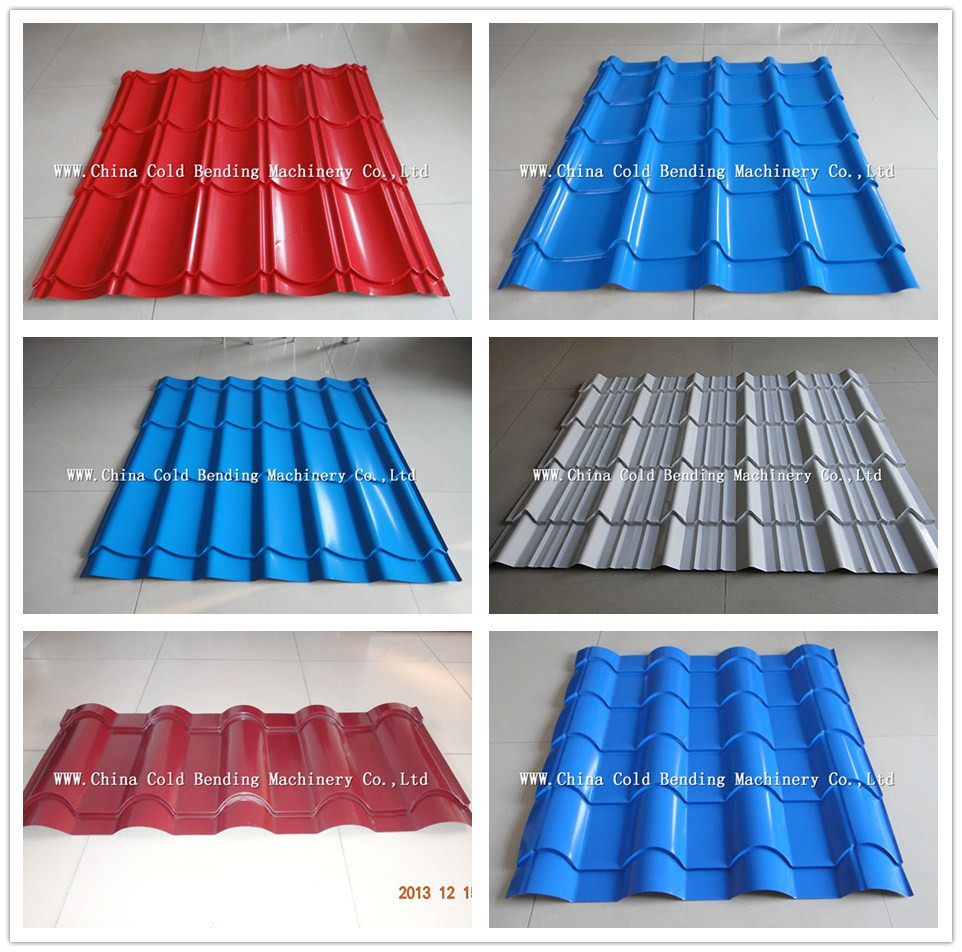

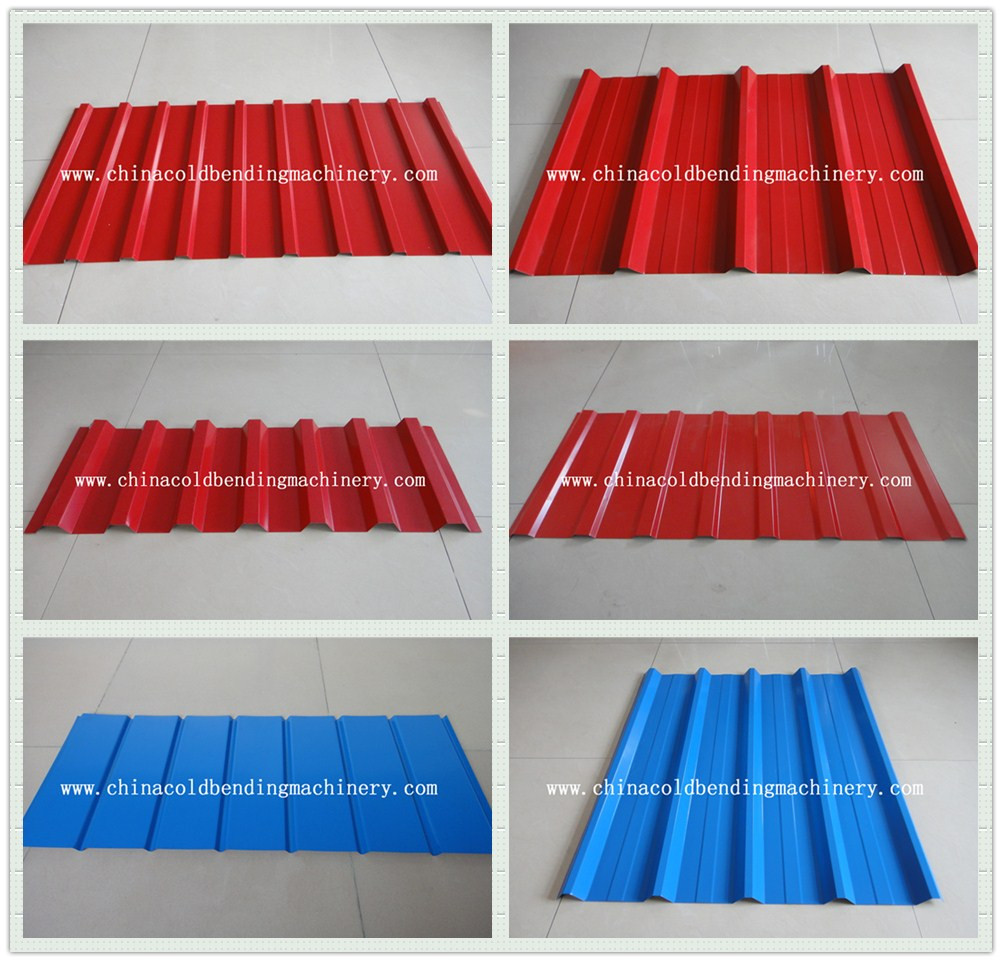

The double roof sheet rolling machine can be used in a limited space . It can produce the two different types . Corrugated panel , trapezoidal panel and glazed panel , Choose any two of them , we can make it by one set of machine .

The cutting system of the double deck roll forming machine can be up and down . When the up layer working , the blade go up to cut the plate . When the down layer working , it will go down to cut .

The cost of the double layer roll forming machine is much lower than the two sets of the single layer roll forming machine .

Main Parameter Of Two Layer Roof Panel Machine

* Roller Stations: Up Layer : 11 Station, Down Layer : 14 Station

* Material of roller : 45# H steel plate with chrome * Shaft : 45# H steel, 70mm

* Material of main body : 350mm H steel * Working Speed : 8-12 m / min

* Power : Main Power is 3Kw, Hydraulic Pump : 3Kw * Driving Way : By Chain

* Weight of Machine : About 5.5 Ton * Dimension : 6600 * 1510 * 1550 mm

* Voltage : 380V 50Hz 3Phases or Customerization * Operation : Manual and Automatic

* Blade : Cr12, Heat Treatment

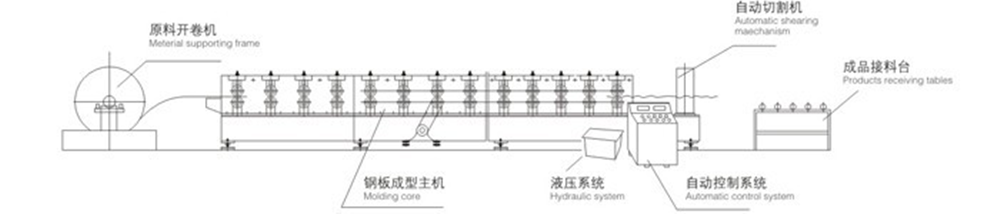

Layout Of Double Layer Roll Forming Machine

Component of Double Layer Roll Forming Machine

* 5T Decoiler............................1 Set

* Main Roll Forming Machine............................1 Set

* PLC Control Cabinet............................1 Set

* Hydraulic Station............................1 Set

* Hydraulic Cutting Device............................1 Set

* Product Receiving Tables............................2 Set

* Spare Part............................1 Set

More Different Shape Roof Sheet

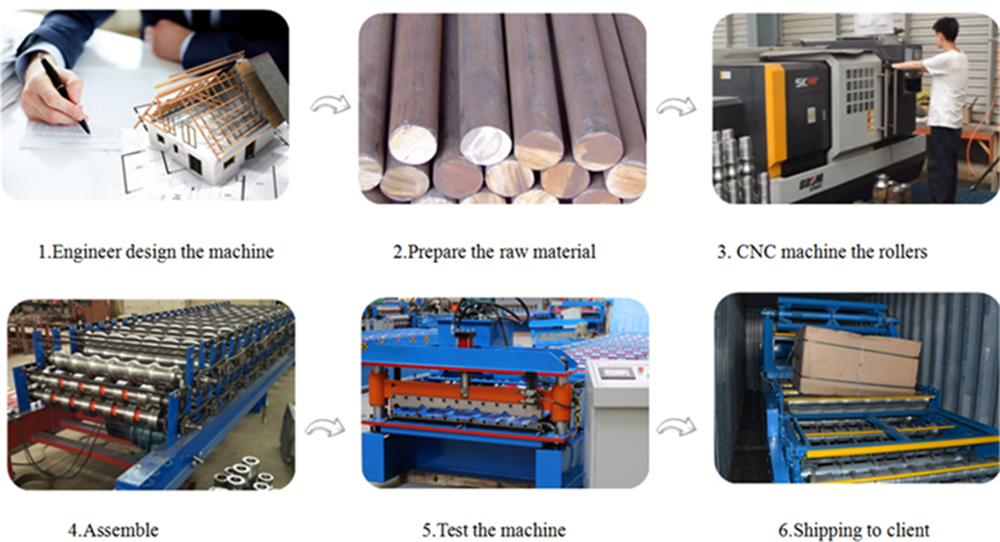

Produce Flow Of Machine

Application

This type of sheet can be widely used in plant, house, storage and simple steel roof and wall. It has advantage of pretty appearance, durable using and so on.

Company information

Kaiyite machinery is a leading manufacture of roll forming machine . We know well the particular requirements for the customers from different countries , and have an outstanding export team who will take your requests . Our experts and skilled workers complete the work with great precision .

We provide an extensive line of products , including roller shutter door roll forming machine ,door frame machine, roof and wall panel roll forming machine , double layer roll forming machine ,floor deck roll forming machine ,C / Z / U Purlin Roll Forming Machine , stud and track roll forming machine , ridge cap roll forming machine , downspout pipe roll forming machine , shearing machine and bending machine , slitting and cutting machine .

Product Categories : Double Layer Roll Forming Machine